27/02/2023

Wet-glue labels for wine or beer are applied to glass bottles, both front and back labels, sometimes also neck labels. Besides printing, other embellishments like foiling can be applied but with some limitations as the single labels need to be inserted in a nice stack before they get applied. The materials used are papers which can be coated, uncoated, structured, and also metalized to create special effects. Depending on the countries, regional wash-off parameters of the labels can be important to assure they fit into the recycling process. The label is applied at the packaging line by first applying glue on the container and then applying the single label.

What is the value of digital printing?

A growing consuming trend of craft beers and much more diversity in the beer market creates the need for shorter runs. There is a large number of wet-glue label applicators installed in the market so rather than going to another decoration technique (such as self-adhesive labelling) there is a large potential for short-run labels. Today’s choice of substrates, workflow and finishing enables printers to go digital for small series and customized runs in wet-glue labels.

Furthermore digital printing with Xeikon offers:

a true complementary production solution to your conventional printing presses

reliableness and robustness able to sit alongside your offset press environment

Which is the preferred digital press for wet-glue beer labels?

The Xeikon CX500 digital label press. The outperformer of all high quality dry toner digital label presses in terms of productivity, thanks to its unique web width (up to 520 mm/20.47") and its full rotary printing with speeds at 30 m/min (98 ft/min) or 2,500 B2 sheets/hour:

dry toner technology: allows you to achieve high quality, even on challenging print media, e.g. opaque white toner allows to print on the wide range of materials used for beer labels (paper and silver faced papers)

B2 format: ensures productivity and provides a digital complement to conventional printing by using the same finishing process

roll-fed printing: ensures higher productivity and reduces the material waste

high quality printing: 1200 dpi allows to achieve offset quality level or beyond

Which is the preferred digital production solution?

Below you can see an example of a full production set-up for wet-glue beer labels: roll-to-sheet line including a Xeikon CX500 digital label press, a Web Varnishing Module which adds a high-quality UV or water-based coating for protection, Sheeter and Waste Separator and a Pile High Stacker. It is our complete digital printing solution, which comes with all the necessary components for seamless digital label printing.

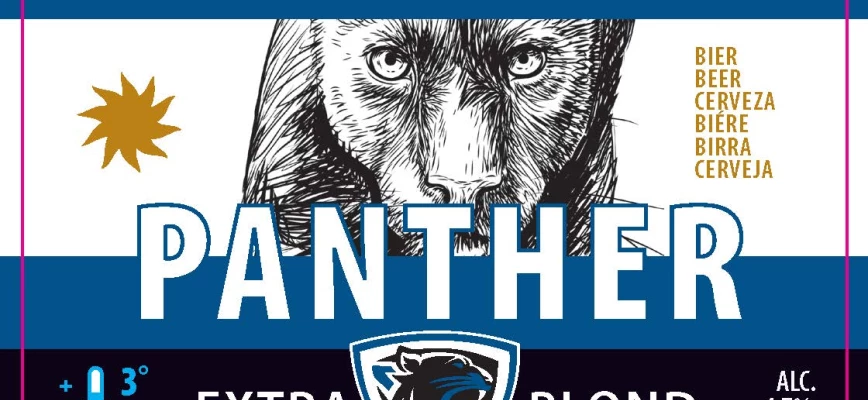

Here you can see a wet-glue beer label sample printed on a Xeikon CX500 digital label press.

Print dimensions: 90 x 65 mm

Substrate: Special label paper for non-returnable use with smooth metalized surface

Toner: CMYK + one-pass opaque White Cheetah toner

Finishing: Inline/water-based varnish, offline/rotary die cut

The Xeikon CX500, our fastest dry toner press in the portfolio, has been the press of choice due to its ability to print B2 format sheets or reels. With its speed and Cheetah toner it is the most economic printing press and the 5 print stations enable for laying down white and CMYK.