Labels

Leveling up in label printing

Whether you’re laying groundwork for hefty capacities or simply getting your foot in the door, label printing is an oyster of opportunity. As your digital printing partner, Xeikon is proud to step in with smart workflows and unique solutions to diversify and finesse your end-use.

UV Inkjet or Dry Toner; your choice!

With Xeikon’s label printing presses, you no longer have to choose between UV Inkjet or Dry Toner. We offer both… complete with guidance to help select the right technology.

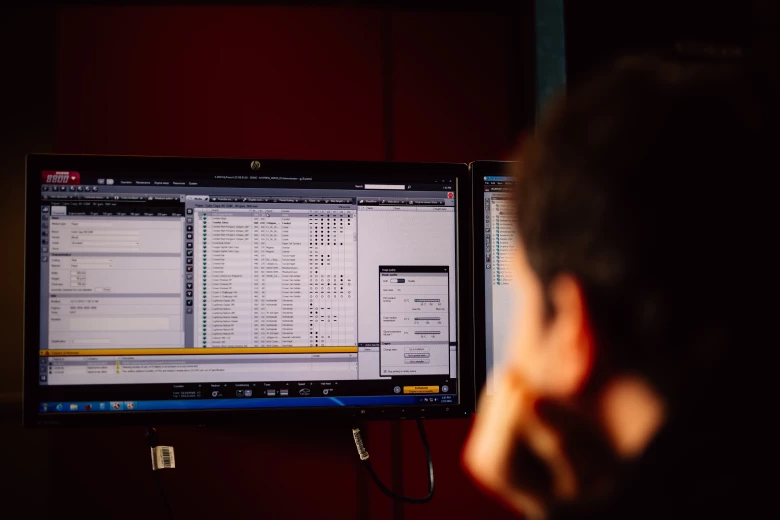

Innovation & security at your fingertips

The product needs to stand out… and the sky’s the limit. Xeikon’s seamless integration let’s creativity take the reins, providing security specific data as well as innovative solutions.

Quality that fits any run length

Run lengths are changing, and Xeikon helps your customer adapt either way… promising highest quality deliverables with converting that saves time and proves to serve with efficiency.

Hit your label printing goals

Solutions that combine the right presses and products to fit your needs

Discover how you can optimize your workflow

Is your company riding the digital label printing wave? Or do you hesitate about whether digital label printing can maximize your success? With our online survey, you can discover for yourself how digital label printing optimizes your business.

Xeikon's spotlight on:

31/10/2023

by Donna Covannon

13/07/2023

by Filip Weymans

01/03/2023

by Filip Weymans

Label printing; presses for success

Find the solution that's right for you.

Cheetah

Panther

REX

Our approach

Relevant applications

Blog

Label printing, your way; self adhesive label suite

Self-adhesive labels have seen a rapid increase in product variety as of late. A thrivingly diverse customer base is rearing its head, challenging how brands and retailers cater to its demands. What

How we continue to support you

Regardless of whether you are just starting to use our digital printing technology, have been using it for some time, or want to use it in an even more optimized way: count on Xeikon for the entire life cycle of your solution.

Discover all our services